|

|

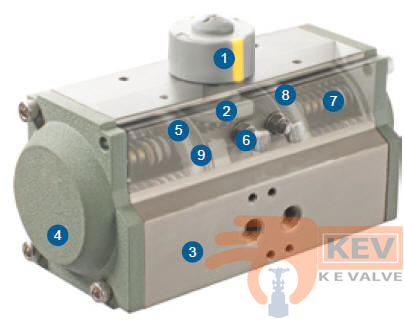

5. Pistons

The precisely-balanced and hard anodized treatment (over 30um) die cast aluminum pistons are fitted with

high quality rings and guides. The twin rack and piston design creates a constant torque output on all

actuators.

6. Travel Adjustment

The standard adjustment is + 5° in both the open and closed positions through easily accessible external adjustment bolts.

7. High Performance Springs

The high tensile steel springs are coated with zinc phosphate for corrosion resistance and longer service.

The pre-loaded springs can be safely & rapidly disassembled.

8. Bearings and Guides

The highly durable compound material provides high trust stability with minimum friction and long life.

9. O-Rings

NBR O-rings provide trouble-free operation at standard temperature ranges. Viton and Silicone O-rings are

available for high or low temperature applications.