Check valves are used to allow fluid flow in a system in only one direction. They are operated by the flow of fluid in the piping. A check valve may be the swing type, lift type, or ball type. Most valves can be classified as being either stop valves or check valves. Some valves, however, function either as stop valves or as check valves-depending on the position of the valve stem. These valves are known as stop-check valves.

|

|

|

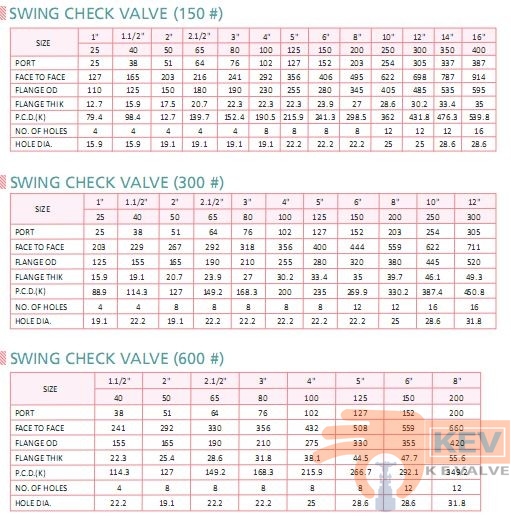

Flanged End Swing Check ValvesPN 10/16/25/40 CLASS 150/300/600/900/1500 JIS 10K/20K |

Flanged End Swing Check ValvesClass 150/300/600/ 900/1500/2500 |

|

|

|

||

|

|

|

Dual Plate Check ValvesCLASS 150/300/600 PN 10/16/40 |

Single Door Check ValvesCLASS 150/300/600 PN 10/16/40 |

Disk Check ValvesPN 40 |

|

|

||

|

|

|

Flanged End Check ValvesCLASS 150 PN 16 |

Screwed End Swing Check Valves200 W.O.G. |

Screwed End Piston Check Valves800 WOG PN50 |

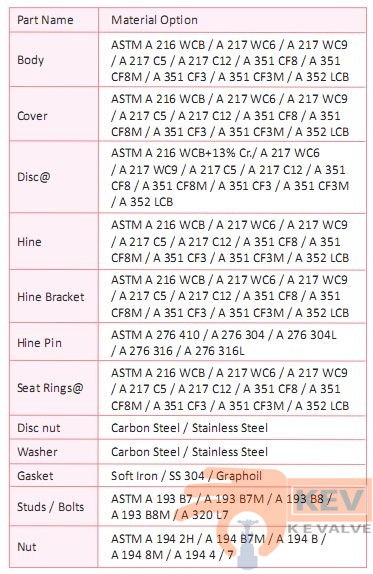

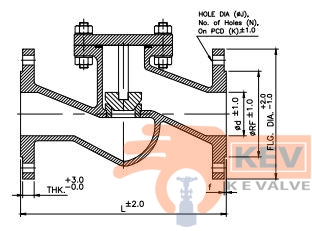

Swing Check Valve

Special Features

- The Body to Bonnet joint is a male & female as per ASME 1501.3001 & 6001 and ring joint is used In higher classes valves.

- Valves meet the requirements of fugitive emission levels Shell category-B as per MESCSPE 77 / 312

- Low Friction Losses

- Drip Tight Seating

- Low Maintenance

- No Hinge Pin or spring to Wear

- Easy in-line serviceability

Options in Swing Check Valves

- Check Valves can be supplied with counter weight or dash pot arrangement

- Available in tilting disc design

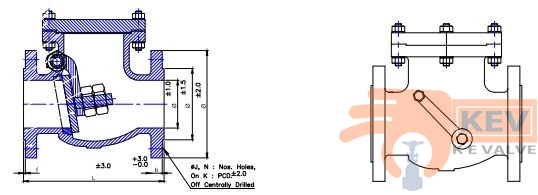

Dimension

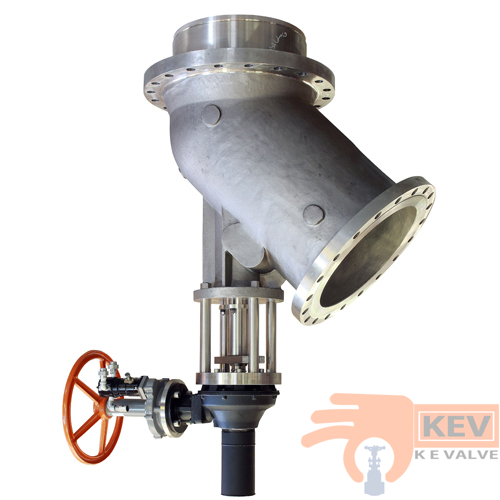

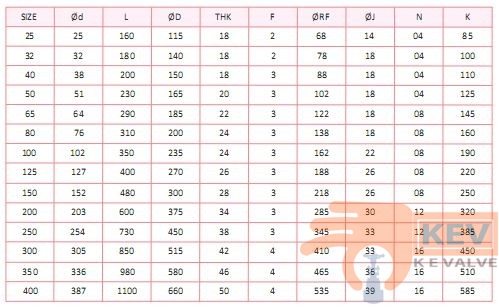

LIFT UP CHECK VALVE

Dimension

- Dimension and other engineering data are subjected to change without notice.

- Other flange drilling also available on request.